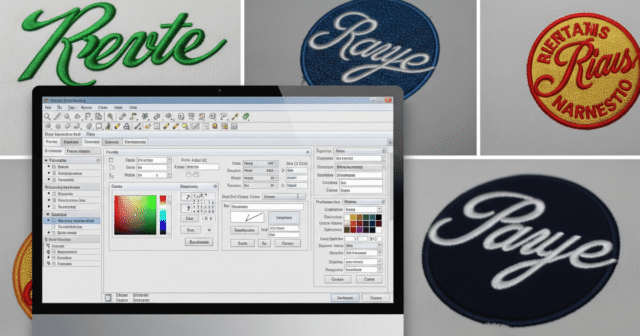

Embroidery offers a tactile and professional finish to textiles, but its quality depends heavily on the behind-the-scenes file creation. This is where custom embroidery digitizing comes into play—building precise instructions that guide machines to stitch logos and designs cleanly and consistently.

In this article, we’ll explore the ins and outs of custom digitizing, how it differs from basic automation, and why it plays a crucial role in successful embroidery production.

What Is Custom Embroidery Digitizing?

Custom embroidery digitizing is the manual process of converting graphical artwork—such as logos or illustrations—into stitch files (like DST, PES, EXP, or EMB). Unlike automated conversion, custom digitizing involves an experienced technician:

- Choosing the right stitch types

- Planning stitch direction and underlay

- Adjusting density for different fabrics

- Sequencing stitch paths efficiently

These choices ensure the final output aligns with both design intent and material behavior.

Why This Process Matters

Embroidery machines read stitch files as precise directions. Custom digitizing ensures:

- Clean Lines & Shapes: Curves stay smooth and edges stay sharp.

- Efficient Thread Use: Avoids excess jumps and trims.

- Fabric-Friendly Stitching: Prevents puckering or distortion.

- Consistent Output: Ensures design integrity across repeats.

In the absence of custom digitizing, designs become prone to misalignment, poor stitch quality, and wasted materials.

Custom vs. Auto Digitizing

Here’s a snapshot comparison:

| Feature | Auto Digitizing | Custom Digitizing |

|---|---|---|

| Stitch Planning | Generic and unoptimized | Tailored to design and fabric |

| Density Control | Inaccurate defaults | Calibrated per project |

| Path Efficiency | Random stitching paths | Streamlined, efficient order |

| Detail Preservation | Often lost or distorted | Maintained with precision |

| Format Support | Limited choices | Multiple machine-ready outputs |

Custom digitizing treats each design uniquely, improving final stitch performance and appearance.

Benefits of Quality Digitizing

- Improved Quality: Crisp details and accurate fills

- Speedy Production: Less machine downtime

- Consistent Branding: Repeatable logo reproduction

- Versatile File Use: Works across various garments

- Cost Savings: Less thread waste and fewer rejects

Essential File Formats

Top digitized formats include:

- DST – for Tajima machines

- PES – for Brother/Babylock machines

- EXP – used by Melco

- EMB – editable Wilcom format

- Plus others like XXX, JEF, VP3 depending on machines

A good digitizer will provide all needed formats for your production setup.

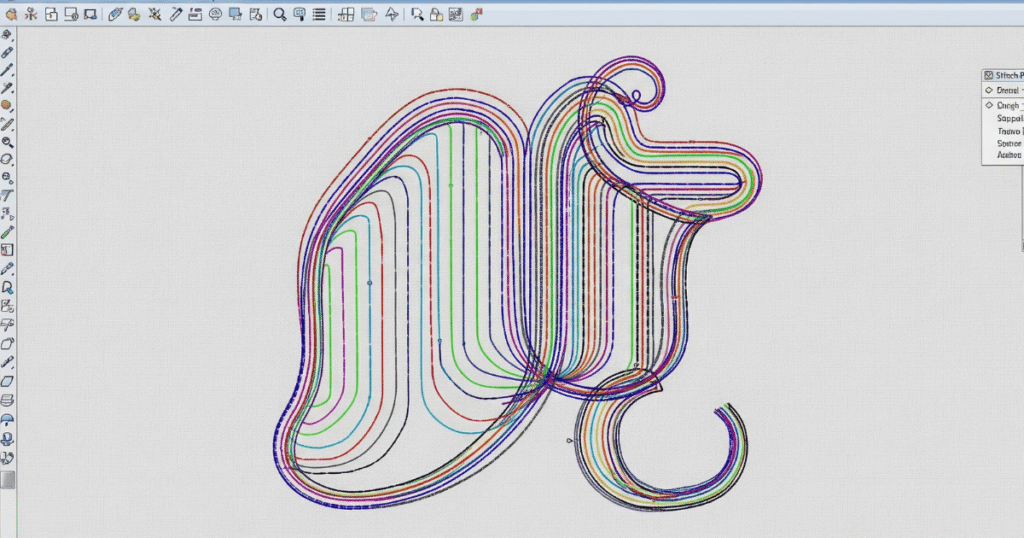

How the Digitizing Workflow Works

- Collect high-resolution artwork (vector or good-quality raster)

- Analyze fabric type and required output size

- Plan stitch techniques, underlay, and density

- Build paths within digitizing software

- Simulate and test stitch preview

- Adjust after sampling on physical material

- Export files in requested formats

This systematic approach ensures both accuracy and efficiency.

Who Benefits Most

Digital embroidery work benefits:

- Apparel brands needing consistent visual identity

- Sports teams with numbered and logoed gear

- Promotional product suppliers

- Etsy and e-commerce sellers

- Event organizers customizing staffwear

Any project relying on trust-worthy embroidery gains from customized digitizing.

Common Issues and Expert Fixes

| Issue | Root Cause | Custom Digitizing Fix |

|---|---|---|

| Fabric Puckering | Improper underlay/density | Material-specific settings |

| Broken Threads | Poor stitch sequencing | Optimized stitch planning |

| Distorted Curves | Lack of pull compensation | Correct stitch direction |

| Excess Trims | Overabundance of color jumps | Grouped color sequencing |

| Format Mismatch | Wrong file type for machine | Multi-format export |

Tips for Working with Providers

- Provide clear artwork and output specs

- Specify materials and desired stitch size

- Request sample stitch-outs for approval

- Ask for all relevant machine formats

- Confirm if revisions are included

Clear communication leads to smoother digitization and better results from the start.

Supporting Industry Insight

Production data shows up to 40% fewer thread breaks and 20% faster setup times when using expertly digitized embroidery files, making it a worthwhile investment.

Summary

Custom embroidery digitizing is both an art and a science—transforming creative designs into technical instructions that bring accuracy, efficiency, and quality to embroidery projects. Whether for caps, uniforms, or promotional gear, investing in high-quality digitizing ensures your finished products faithfully match your brand’s vision.

Ready to elevate your embroidery production with expert digitizing?